The objective of production planning and control is to plan and manage the materials and capacities based on the customer needs. Thus production planning enables the company to fulfill customer demand and achieve other goals efficiently and with high quality.

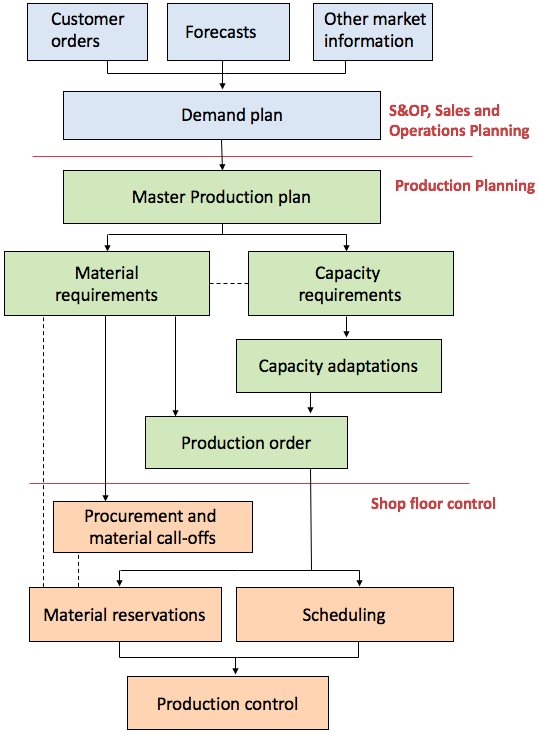

The chart below depicts the elements of production planning and control on a high level. There are differences between industries in production planning and control, so the practical work of production planner as well as the order and emphasis of different stages may differ strongly depending on the industry and company.

Production planning is based on (customer) demand. In modern operations the demand is planned actively combing mathematical forecasts with different expert knowledge about future demand making decisions in order to base future actions into shared information. This planning and decision making process is often called S&OP, Sales and Operations Planning. Besides planning the demand, S&OP typically includes also the balancing of demand and supply. Therefore production planning can be understood as a part of the S&OP-process, or at least its important “partner process”.

The two key areas of production planning are materials and capacity planning. Based on the jointly agreed and shared demand plan, the next step is usually to create a master production plan on a rough level. Material needs are calculated based on this plan and taking into account existing inventories and expected arrivals of material supplies. This information about future material needs is the basis for purchasing and material replenishment orders and call-offs. Besides the material needs, also the capacity needs for production are determined. In some cases the capacities have to be considered also outside of production, for example if warehousing or transportation capacity may become a bottleneck. There may be a need to adapt by increasing (or decreasing) either personnel or machine capacity, or for example by outsourcing.

The production plan is refined typically into more detailed material and capacity plans, to production orders and into materials reservation as well as loading and scheduling of individual work stations. The first steps of the production planning process are usually carried out in an IT-system. The shop floor control may be in IT system, or a manual visual system, or a combination of these two.

Page updated / checked 2.1.2025.